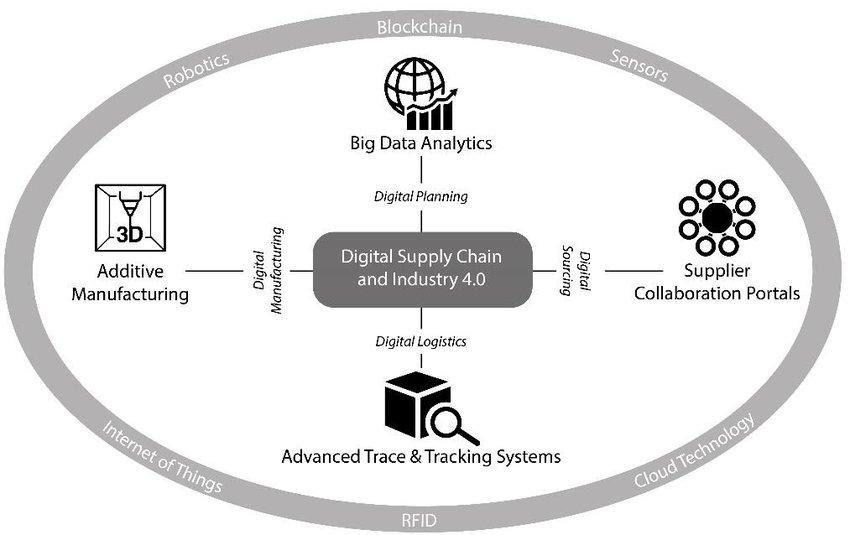

Digitization of the supply chain has been transforming supply chain processes and making it more efficient. Digital or Smart packaging, Electronic cargo tracking systems, RFID E-seals all provide better security and have contributed to the acceptance of a digital supply chain ecosystem.

Track and Trace technology has changed the way people manage supply chain operations. Having a track and trace framework saves unpredictable expenses, while maintaining product quality and catching any product related problems easily.

It is the goal of any industry to increase the efficiency of all the departments. Since supply chain plays a pivotal role to propel business growth all around the world, improving its efficiency can benefit a lot. Let’s look at seven ways how track and trace technology helps in improving the supply chain efficiency:

- Incorporating Track and Trace technology in inventory can maximize its efficiency in a lot of ways. It is important to plan your inventory, measure its accuracy and even undertake forecasting.

Regular updates and alerts keeps you informed about the inventory available. This greatly reduces inventory costs as it gives better understanding of the stock in and stock outs. - Supply chain involves many stake holders like distributor, retailers and manufacturers. Track and trace enable greater collaboration and knowledge sharing among them and thereby increases the overall efficiency.

Many a time, energy and resources are spent to keep everyone in the loop informed about the products in transit. This also helps the customers to have a track of things they are expecting. - One of the major responsibilities of any industry is delivering the order on time. This is achieved with track and trace features. The effective use of data and its analysis over a period of time can help you make better decisions and improve supply chain performance.

- Data analysis through track and trace can prevent defective parts from reaching the customer and thereby minimizing losses. You can now track products at each SKU level, map it to raw material used in its manufacture through which any defective products that were produced can be traced back right to its source.

- Theft reduction is perhaps one of the best utilities of track and trace It gives you greater visibility of operations happening internally. Reporting is also far better. Externally, products like RFID E-seal from Sepio are tamper-evident and therefore any fault or short falls during delivery can be found easily.

- Just In Time Manufacturing, Track and trace gives a major boost to Just in Time manufacturing processes. It is widely used in industries all over to increase efficiency and productivity. Supply chain being an integral part of the JIT manufacturing process, requirement of materials and forecasting are all improved with track and trace technology.

- Protecting brand reputation is one of the less known advantages of track and trace. The best quality product is supplied to the customer by preventing defective products, unwanted delays in delivery, maintaining inventory and finally by improving production efficiency. This gives the end consumer of your brand peace of mind on knowing where the product came from, how long it took and that it is safe for them to consume.