RFID and Barcodes have been in the market for decades, used by several organizations for asset tracking and inventory management. Though both technologies had emerged at the same time, barcodes found their way into the market, while RFID had difficulty entering. However, the current scenario has changed a lot. Companies started understanding the importance of RFID technology and how it can help in accurate asset tracking and managing inventory with minimal manual errors. But which of the above technologies is best suited for your organization?

What is a Barcode?

Before we proceed toward the major differences between RFID and barcode tracking, it is essential to understand each of them individually. Simply put, a barcode is a representation of data encoded in the form of black and white lines along with some numbers beneath. A barcode scanner is used for scanning and decoding the data, after which it is entered into the computer database.

Barcode tracking, as the name suggests, is the method of tracking assets from inventory to the end consumer with the help of barcodes. One of the major advantages of using barcode tracking is that it’s universal and doesn’t require any change in format in case of imports or exports. However, using barcodes to scan thousands of products is tiring, as each barcode needs to be in perfect sight for the scanner to read it. Besides, barcodes get easily damaged during transportation and weather change, thus making it difficult for the scanner to read.

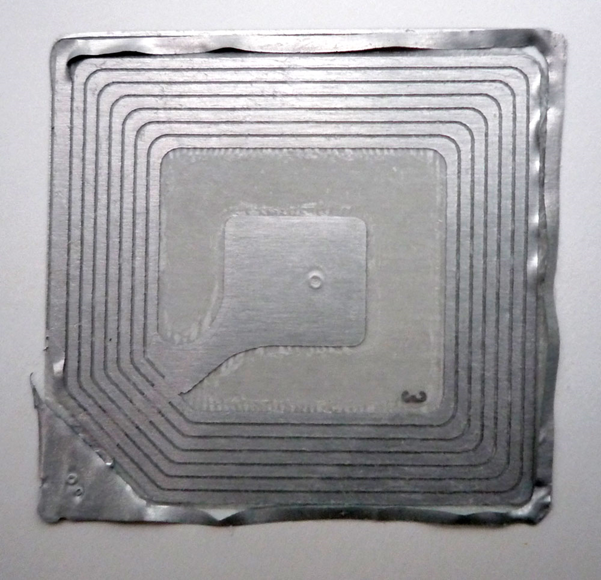

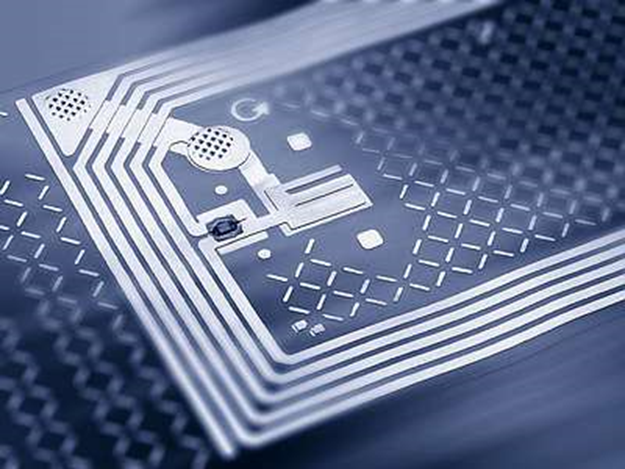

What Is RFID?

Radio Frequency Identification, or RFID, is one of the most popular methods used for asset tracking. It uses small tags or chips that emit radio waves of specific frequencies that the RFID scanner can read.

The best thing about RFID tracking is that you can scan multiple items without an internet connection. Due to this, most companies use RFID solutions in warehouses with severe network issues. Unlike barcodes, RFID tags can easily endure extreme temperature and pressure, which makes them highly durable. However, RFID tracking has its share of disadvantages. For example, one cannot use RFID tags for international asset tracking, as different countries have different rules and regulations. On top of that, RFID installation is expensive and time-consuming. You need to spend time planning RFID trackers in the warehouses so that they do not scan an item multiple times. Moreover, RFID tags can easily get interfered with by liquids and metals.

RFID vs. Barcode: Final Verdict

There are tons of similarities and differences between RFID and barcode, which makes them unique in their own way. But we are here to see which one is perfect for asset tracking.

As proper asset tracking has become the need of the hour, companies must invest in technologies that will provide accurate results. Here are some major RFID and barcode differences that will help you make the correct decision.

Data Storage and Security: The main disadvantage of using barcodes for asset tracking is that they cannot store much data. Each barcode can only store data up to 20 characters, which will hardly include the name and model number of the product. But, RFID gives you the benefit of storage. Each RFID tag can store thousands of data points, including product origin, serial number, manufacturer details, etc. Besides, RFID tags are difficult to duplicate, whereas one can easily print a copy of the barcode.

Accuracy: When it comes to accuracy, barcodes are said to be more accurate as you need to position them near the scanner for the device to read them properly. With RFID tracking, multiple scanning of the same item is possible. That’s why warehouses separate the item palates with metal bars so that the reader won’t make a mistake.

Speed: Both RFID and barcodes are accurate but have certain limitations. With barcodes, you need to put the product in the proper line of sight so that the scanner can read the data, which takes up a lot of time. But, RFID can scan multiple tags within seconds, even from a long distance.

Setup & Training: When we come to pricing and installation, barcodes have the upper hand in here. They are cheaper and do not take much time for installation. Besides, training employees to handle packets with barcodes won’t take more than a day. But, with RFID tags, it’s a tough journey with benefits in the long run. The entire setup for RFID tracking is expensive and needs proper planning to avoid mistakes. Moreover, you need to provide a proper training session to your employees so that they can handle the process.

Both barcodes and RFID have their own share of pros and cons. But, when it comes to choosing one of the above, the decision lies entirely on your business type and requirement. Barcodes are perfect for small-scale industries, where you can scan the items individually without difficulty. However, when it comes to medium to large-scale organizations with a higher volume of shipments, RFID tags will be a preferable choice. That’s because the RFID reader can scan all the items at once without any difficulty bringing major efficiency gains to your operations.

If you want to know more about barcodes and RFID tracking tags, contact Sepio Products at hello@sepioproducts.com.